In today’s world, it is essential for manufacturing businesses to keep track of materials and their movement in order to maintain an efficient production workflow. With the right tracking system in place, a business can better manage its budget and resources while minimizing product waste. Fortunately, there are several different approaches to material tracking that make it easier for companies to stay organized and maximize efficiency. In this article, we'll explore the different types of material tracking systems available and discuss how they can help businesses streamline their operations.

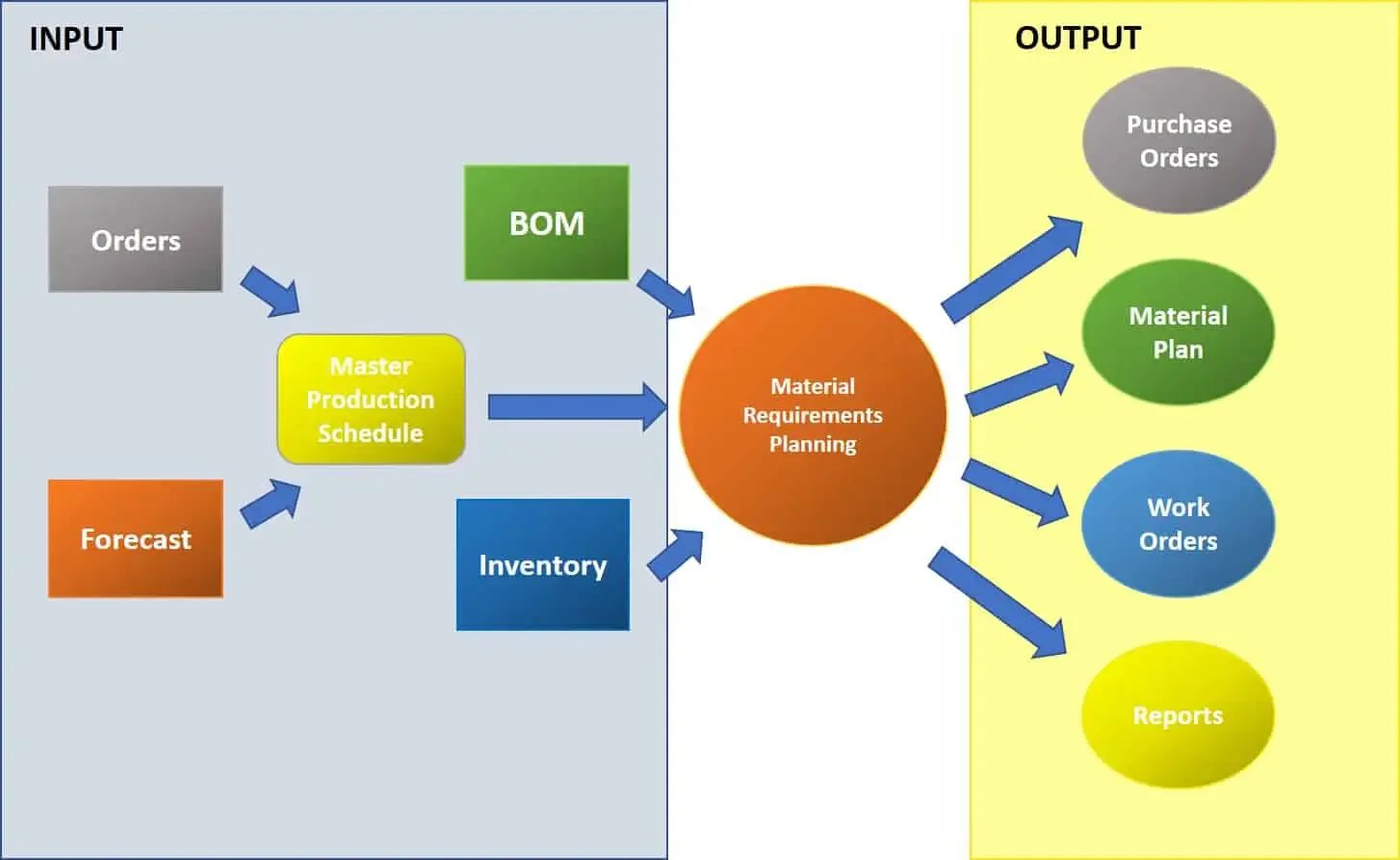

Look Into Key Formulas:

A key formula is a way of determining the components needed to make up an item that you're manufacturing. This type of tracking system helps businesses calculate exactly how much material and other resources are needed for a particular product or process. By understanding the exact recipe for each of their products, companies can accurately track inventory levels and keep their costs in check. Experts from Katana MRP recommend focusing on the

Reorder point formula to maximize sales and minimize overhead costs. This simple formula calculates the point where a company needs to reorder materials for production and shows exactly how much to order when the time comes.

Learn About Batch Tracking:

Batch tracking is essential for any manufacturing business, as it allows you to keep track of the materials and components used in your products. With batch tracking, you are able to trace each item back to its origin, ensuring that only high-quality materials go into the product. It also helps you identify defects quickly and respond proactively to improve your processes. Batch tracking also helps you keep track of the cost associated with each material, and ultimately increases your profitability.

With the right software solution, batch tracking can be an invaluable tool to help optimize your manufacturing process. Batch tracking not only helps manufacturers maximize production efficiency and accuracy but also makes sure that all of their materials are properly tracked and accounted for. This allows you to better manage inventory, reduce waste, and ensure quality assurance.

Backordering:

Backordering is a common practice for manufacturers to ensure that they always have the raw materials needed to keep production going. This process involves creating an order for items before all of the material has been purchased and received. The order will then be placed on “backorder”, with suppliers being notified when the materials are ready to ship out.

Backordering can be used to reduce costs and ensure that materials are always available when they are needed. It is important to track backorders closely so that production timelines remain on schedule and no materials run out unexpectedly. This will help keep your business running smoothly and efficiently.

Negative Inventory:

Negative inventory is a situation where the number of items in stock appears to be lower than it actually is. This can occur when an inventory system records outgoing materials or products as having been used, but not yet received. To avoid negative inventory, manufacturers must keep track of material flow and maintain accurate records for all incoming and outgoing products.

By doing this, businesses can ensure accurate records and avoid material losses or discrepancies. Furthermore, keeping an accurate record of stock materials provides a better understanding of what is available in the inventory and allows a business to make informed decisions about when to purchase additional supplies. It also helps to prevent overstocking, which can cause unnecessary cost increases.

.webp)

Inventory Forecasting:

Inventory forecasting plays a crucial role in manufacturing businesses, allowing them to effectively track and manage their material investments. By accurately predicting future needs for materials, manufacturers are able to better plan their production cycles, optimize inventory levels with minimum waste, and reduce the likelihood of supply chain disruptions.

With proper inventory forecasting tools and techniques, manufacturers can streamline their operations and ensure the timely delivery of their products. Additionally, inventory forecasting can help manufacturers save money by allowing them to accurately predict materials and resources needed for upcoming projects. As such, it is an important part of the supply chain management process that should not be overlooked.

Demand Planning:

Demand Planning is a critical part of materials tracking for any manufacturing business. It involves forecasting future customer demand and planning inventory accordingly. This helps ensure that the right materials are always on hand when needed, reducing downtime and improving efficiency. The most accurate demand plans require data from multiple sources, including historical sales figures, market trends, customer feedback, and competitor information.

With the right data, businesses can make accurate predictions and ensure materials availability when it's needed most. By understanding customer demand, manufacturing companies can better plan their operations and optimize their processes accordingly. Demand Planning is an essential part of any successful materials tracking strategy.

Analyze Your Inventory Carefully:

Analyzing your inventory is an important part of tracking materials for a manufacturing business. Taking a careful look at what you have in stock, what you are ordering and the rate of turnover can provide valuable insights into how efficiently your production process is working. It can also help to identify areas that need improvement so that you can better manage costs while ensuring that you have the materials you need to produce quality products.

Paying close attention to your inventory can help streamline operations, improve customer satisfaction and ultimately increase profits for your business. To get started, consider tracking things such as stock items, current orders, purchase dates and quantities, delivery times, and any other relevant data that might provide useful information. By analyzing your inventory and making informed decisions, you can ensure that your business runs smoothly while maximizing the efficiency of your production process.

In conclusion, effectively tracking materials for a manufacturing business is essential for successful operations. By utilizing inventory forecasting, demand planning, and careful analysis of current materials, businesses can gain valuable insights into their production processes while optimizing their operations to maximize efficiency and save money. Properly managing your material resources can have a significant impact on the success of your business and should be treated as an important part of your overall supply chain management strategy. With the right tools and techniques, you can ensure that your business always has the materials needed to produce quality products in a timely manner.

.webp)